Fully Automated Tightening of Bolts in WTG Flanges

AutoBolt Technology:

- Autonomous operation

- Installation time 15 minutes

- Battery operated

- Eliminates need for rattle guns

- Bolt sizes up to M100

- Speed 25 sec per M64 bolt

- Full documentation to bolt-level

- Elimination of HSE risks

- Sigma 3 quality on-Site

- Patented technology

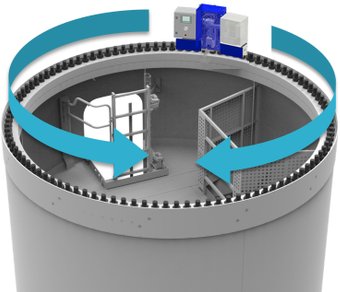

Autonomous Process

AutoBolt is mounted on the flange and will after initiation by the operator perform tightening of all bolts in a fully autonomous process according to a pre-defined tightening schedule

Freedom of Tower Design

The reduced variance and increased bolt pre-tensioning forces made possible by the AutoBolt technology provides more freedom in the design and optimization of WTG towers, including reduced flange widths and thicknesses, and reduced bolt diameters.

Faster Installation

The fully automated process for tightening of bolts elimates manual labour and reduces time consumption significantly.

No need for re-tightening

Tightening of bolts according to certified tightening schedules combined with tamper-proof validation data elimates the need for re-tightening with a loose bolt being categorized as a defect.

Cost Savings

Significant cost savings due to faster installation processes with reduced crane time and fewer personnel man-hours, reduced material consumption in flanges and bolts, and elimination of need for re-tightening of bolts during WTG lifetime.

Automatic Data Collection

AutoBolt eliminates the need for Smart Tools. Fully independent from the tool and pump brand, AutoBolt collects all relevant data from the tightening process, including bolt-ID, applied hydraulic pressure, and angular turn-of-the-nut, and stores these in an encrypted documentation file while at the same time removing any risk of human error.

Improved HSE

The elimination of the manual tightening process removes the risk for installers of white finger syndrome, hand and finger injuries, injuries caused by repetitive lifting of heavy material, and accidents caused by leaks of hydraulic oil from hi-pressure hydraulic hoses.

Tool Brand Independent

AutoBolt is fully independent from tool and pump brands. This provides freedom to choose supplier of suitable elongation tools, hydraulic pumps, and even control panels. AutoBolt has integrated gearboxes for attaching puller bars to the bolts and for rotating the nut. Essentially turning any "dumb" tool into a "smart" tool.