AutoBolt Product Range

We offer rental of AutoBolt equipment at a fixed price per flange. We can also offer IP licenses for the technology.

Modular Design

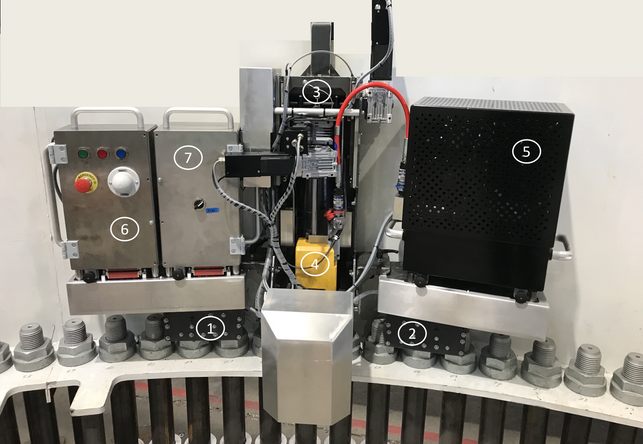

A complete AutoBolt system consists of 7 units:

- The Left Caterpillar is a propulsion module that together with the Right Caterpillar moves AutoBolt clockwise and anti-clockwise along the flange. It supports the Control Cabinet, the Battery Pack, and the left side of the Elevator Unit

- The Right Caterpillar is another propulsion module that in conjuction with the Left Caterpillar moves AutoBolt clockwise and anti-clockwise along the flange. It supports the Hydraulic Pump Unit and the right side of the Elevator Unit.

- The Elevator Unit carries an Elongation Tool. It can lower and lift the Elongation Tool and also contains drives that: (a) attaches/de-attaches the tension nut onto the bolt threads and (b) tightens nut.

- Elongation Tool (3rd party delivery; AutoBolt can be adapted to use with any supplier)

- Proprietary ADMEDE Hydraulic Pump Unit capable of tightening bolts up to Ø100mm at a pressure up to 2,000 bar

- Control Unit with wireless link to control tablet/smartphone

- Battery Pack with 100% extra capacity to tighten all bolts in a full flange

Main Specification Data*

Property | AutoBolt M36-M48 | AutoBolt M56-M72 | AutoBolt M80-M100 |

Bolt Sizes | M36, M42, M48 | M56, M64, M72 | M80, M90, M100 |

Flange Diameter | 3 to 6 meters | 4 to 6 meters | 5 to 8 meters |

Operation Speed | 20 sec/bolt | 25 sec/bolt | 30 sec/bolt |

Assembly Time | 10 min | 10 min | 10 min |

Weight, Caterpillar | 18 kg each | 22 kg each | 26 kg each |

Weight, Elevator Unit | 22 kg | 25 kg | 30 kg |

Weight, Control Cabinet | 20 kg | 20 kg | 20 kg |

Weight, Elongation Tool** | 15 - 25 kg | 40-70 kg | 60 - 90 kg |

Weight, Hydraulic Pump | 35 kg incl. oil | 35 kg incl. oil | 35 kg incl. oil |

Power Supply | 48 V, battery-operated | 48 V, battery-operated | 48 V battery-operated |

Battery Capacity | 4 hours of operation | 4 hours of operation | 4 hours of operation |

Availability | Q1 2025*** | Q1 2025*** | Q1 2025*** |

* Depending on customer specification, variations to figures may occur

** Depending on supplier of elongation tool and hydraulic tool

*** Lead-time 6-9 months

Tool-less Assembly

Prior to mounting AutoBolt on the flange, the Elongation Tool is placed over a bolt.

The two Caterpillars and the Elevator Unit are then placed on the flange separately and easily connected by the operator with a "click"-solution without any need of tools.

Thereafter, the Control Cabinet and the Battery Unit is installed onto a Bus-system on top of the Left Caterpillar followed by installation of the Hydraulic Pump Unit on top of the Right Caterpillar.

Finally, cables are connected via easy plug-connections.

No tools are required for any of the assemblies.

Elongation Tool

AutoBolt can be used with any Elongation Tool suited for tensioning of bolts in WTG flange. This secures full freedom for customers with regards to supplier selection.

Since AutoBolt registers all data concerning the tightening process, including bolt ID, hydraulic pressure applied, and angular Turn-of-the-Nut, and also contains drives for attachment of Tension Nut to bolt threads and Nut rotation, respectively, commodity "off-the-shelf" units can be utilized with cost optimization in mind.

Hydraulic Pump

AutoBolt proprietary hydraulic pump is based on a pressure intensifier system. The pump has capacity to tighten bolts up to M100 to a maximum pressure of 2,000 bar.

Battery-Operated Propulsion System

The unique Caterpillar-based propulsion system ensures that AutoBolt drives on top of the nuts with no physical contact to the flange. This feature enables full flexibility with regards to optimization of flange design.

The battery pack secures capacity to tighten a full tower flange with 100% spare capacity.